Quality Control Department

Tasha’s Quality Control department is responsible for ensuring that the final product meets the exact requirements of the project. QC ensures that the necessary quality exists at every step of the project, from raw material procurement to final product inspections, using advanced standards, client spec. and procedures.

The major tasks of QA department are as follows

1. Calibration

Using calibration instruments for all inspection activities

2. Raw Materials

Ensuring that the raw materials are in accordance with the project requirements and standards such as dimension & visual examination, chemical & mechanical analyses, corrosion requirement, …

3. Production

Dimension

Dimension checking throughout the production such as marking, cutting, beveling, fit up, …

Welding checking throughout the welding process according to approved WPS and control all welding parameter such as ampere, voltage, consumable, …

Qualification of welder according to code.

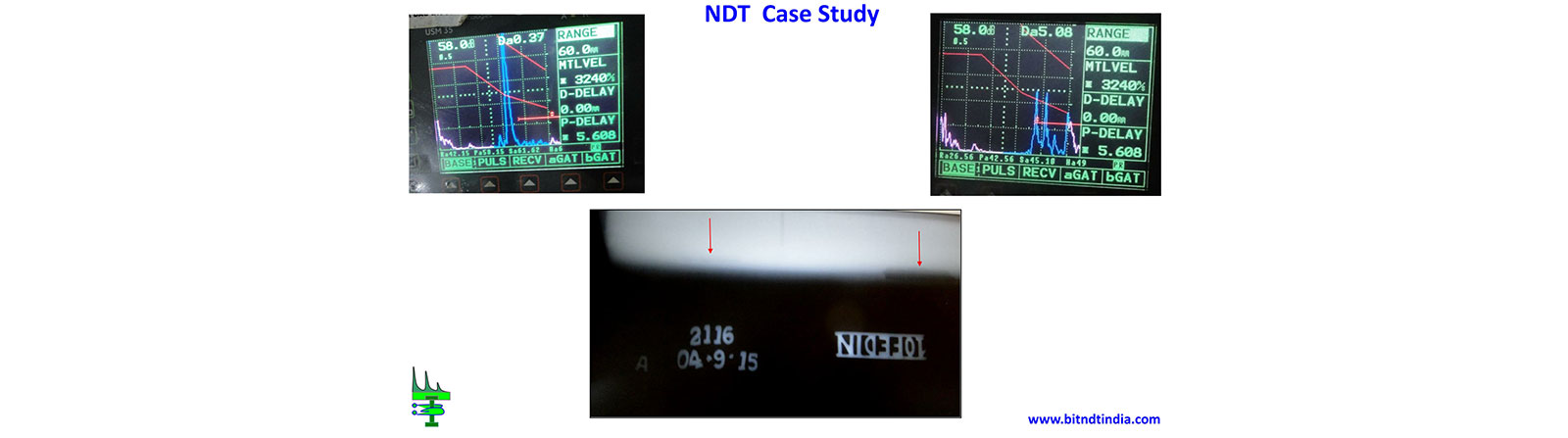

NDT

Applying required NDT activities according to approved welding map and NDT map.

DT

Applying required DT activities using highly qualified domestic and foreign laboratories.

Hydrostatic test

Applying the requisite tests for hydro-test..

Coating

Applying surface preparation and coating such as galvanize, metalizing, painting, …

4. Control

Controlling all levels of inspections using the following personnel qualifications:

ASME member ship

Radiography test level III ASNT

Ultrasonic Test Level III ASNT

PAUT level II CSWIP

TOFD level II CSWIP

Welding international engineer IIW

Radiography Test Level II SNT-TC-1A

Visual welding inspection level II SNT-TC-1A

Liquid penetrant test level IISNT-TC-1A

Magnetic particle test level II SNT-TC-1A

Certificate welding inspection

Using calibration instruments for all inspection activities

2. Raw Materials

Ensuring that the raw materials are in accordance with the project requirements and standards such as dimension & visual examination, chemical & mechanical analyses, corrosion requirement, …

3. Production

Dimension

Dimension checking throughout the production such as marking, cutting, beveling, fit up, …

Welding checking throughout the welding process according to approved WPS and control all welding parameter such as ampere, voltage, consumable, …

Qualification of welder according to code.

NDT

Applying required NDT activities according to approved welding map and NDT map.

DT

Applying required DT activities using highly qualified domestic and foreign laboratories.

Hydrostatic test

Applying the requisite tests for hydro-test..

Coating

Applying surface preparation and coating such as galvanize, metalizing, painting, …

4. Control

Controlling all levels of inspections using the following personnel qualifications:

ASME member ship

Radiography test level III ASNT

Ultrasonic Test Level III ASNT

PAUT level II CSWIP

TOFD level II CSWIP

Welding international engineer IIW

Radiography Test Level II SNT-TC-1A

Visual welding inspection level II SNT-TC-1A

Liquid penetrant test level IISNT-TC-1A

Magnetic particle test level II SNT-TC-1A

Certificate welding inspection

Quality Control Department